Quenching and tempering(QT)

It refers to a heat treatment process used to improve the comprehensive mechanical properties of steel materials.

It refers to a heat treatment process used to improve the comprehensive mechanical properties of steel materials.

Normalizing is a heat treatment that improves the toughness of steel. After heating the steel components to 30~50℃ above the Ac3 temperature, they are kept for some time and then released for air cooling.

Commonly used non-destructive testing methods are ultrasonic testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT), and X-ray testing (RT).

In the production of stainless steel products, some products have strange shapes and cannot be produced by bending and other processes.

1. Carbon steel

2. Carbon structural steel

3. High-quality structural steel

4. Carbon tool steel

The residual elements are one of the main factors for the instability of steel quality. Certain residual elements are prone to segregation and, even at very low levels, can have a strong negative effect on steel properties.

4. Hole defects

5. Cracks and deformation

6 .Other defects

2-2

1. The casting size is out of tolerance

2. The surface of the casting is rough

3. Surface defects of castings

2-1

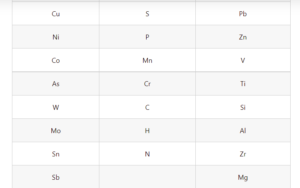

Commonly used alloying elements are chromium, nickel, molybdenum, tungsten, vanadium, titanium, silicon, manganese, aluminum, copper, rare earth, etc.

Low-carbon steel

Medium carbon steel

High-carbon steel

Pig Iron

Steel

Alloy Steel

Investment casting, also known as precision casting or lost wax casting.

Process: Mold material-Wax mold-Group tree-Repair mold-Coating-Sand-Dewaxing-Roasting-Pouring-Cool down-Falling sand-Clean up.

XJL is your premier resource for specialty investment precision castings.

No.6698, Weizhou South Road, Fangzi District, Weifang, Shandong, China.

0086-18365699066

info@xjlpowertech.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@xjlpowertech.com”.

Reach out to us today and get a complimentary business review and consultation.