Summary of Defects Treatment of Steel Castings

Sand holes, air holes, cracks, shrinkage porosity, shrinkage cavities, and inclusions.

Sand holes, air holes, cracks, shrinkage porosity, shrinkage cavities, and inclusions.

Ten guidelines for reducing casting defects, how many do you know?

It is an excellent process technology in the casting industry.

We are all too familiar with surface roughness! However, do you know why the common surface roughness is 0.8, 1.6, 3.2, 6.3, and 12.5?

The commonly used steel grades are 304, 304L, 316, and 316L, which are 300-series steels of austenitic stainless steel.

It is important to emphasize the importance of the operation process.

Quenching, tempering, normalizing, and annealing, do you know the difference?

Investment casting process: how to press wax and group trees?

The characteristics of 4 widely used shell-making processes are analyzed and compared.

Everyone deals with steel almost every day, but do you know the classification of steel?

To obtain steel castings with good quality.

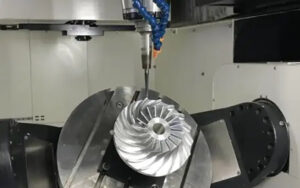

Machining error refers to the degree of deviation between the actual geometric parameters of the part after machining and the ideal geometric parameters.

XJL is your premier resource for specialty investment precision castings.

No.6698, Weizhou South Road, Fangzi District, Weifang, Shandong, China.

0086-18365699066

info@xjlpowertech.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@xjlpowertech.com”.

Reach out to us today and get a complimentary business review and consultation.