Causes of machining errors

Machining error refers to the degree of deviation between the actual geometric parameters of the part after machining and the ideal geometric parameters.

Machining error refers to the degree of deviation between the actual geometric parameters of the part after machining and the ideal geometric parameters.

Magnetic particle inspection uses the interaction between the leakage magnetic field at the workpiece defect and the magnetic powder.

Heat treatment is an important link in machinery manufacturing.

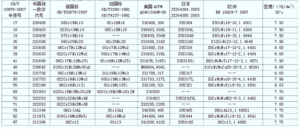

What is stainless steel? Why does stainless steel have different grades?What kind of stainless steel is not easy to rust?

……

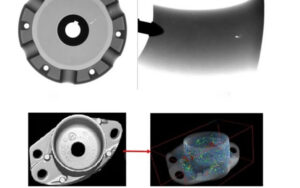

The non-destructive testing technologies include liquid penetrant testing, magnetic particle testing, eddy current testing, radiographic testing, ultrasonic testing, etc.

Machining error refers to the degree of deviation between the actual geometric parameters of the part after machining and the ideal geometric parameters.

A must-have instruction book for heat treatment workshops for foundries.

304 SS is a common material in stainless steel, it is also called 18/8 stainless steel in the industry, meaning it contains more than 18% chromium and more than 8% nickel.

In the manufacturing field, zinc, nickel, and chrome plating are the most widely used.

XJL is your premier resource for specialty investment precision castings.

No.6698, Weizhou South Road, Fangzi District, Weifang, Shandong, China.

0086-18365699066

info@xjlpowertech.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@xjlpowertech.com”.

Reach out to us today and get a complimentary business review and consultation.