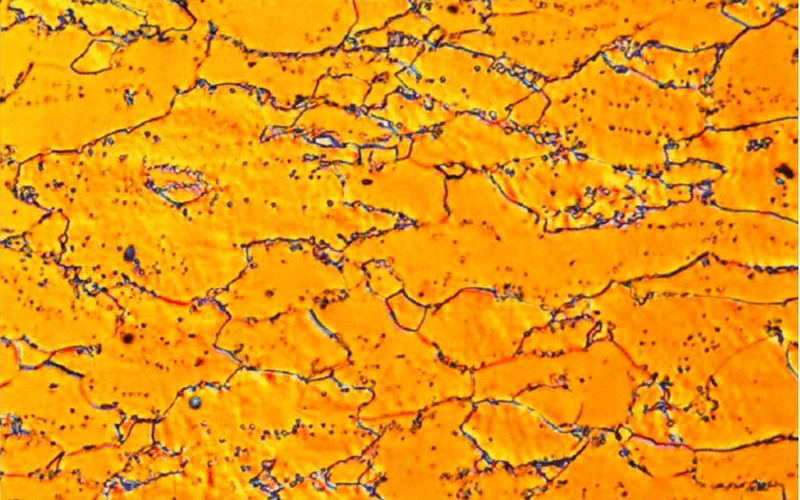

Austenite: carbon and alloy elements dissolved in γ- Solid solution in Fe, still maintained γ- Face centered cubic lattice of Fe.

Features: the grain boundary is a relatively straight and regular polygon; The residual austenite in quenched steel is distributed in the space between martensitic needles.

Ferrite: solid solution of carbon and alloy elements dissolved in a-Fe.

Features:the slow cooling ferrite in the hypoeutectoid steel is massive, and the grain boundary is relatively smooth. When the carbon content is close to the eutectoid composition, the ferrite precipitates along the grain boundary.

Cementite: a compound of carbon and iron.

Features: in the liquid iron-carbon alloy, the cementite (primary cementite) that is crystallized separately at first is blocky, and the angle is not sharp. The eutectic cementite is skeleton-like. The carbides (secondary cementite) that are precipitated along the ACM line when the hypereutectoid steel is cooled are net-like. The eutectoid cementite is flake-like. When the iron-carbon alloy is cooled to below AR1, the cementite (tertiary cementite) is precipitated from the ferrite and is discontinuous flake like on the secondary cementite or at the grain boundary.

Pearlite: a mechanical mixture of ferrite and cementite formed by a eutectoid reaction in an iron-carbon alloy.

Features:the inter sheet distance of pearlite depends on the undercooling degree during austenite decomposition. The greater the undercooling degree, the smaller the distance between the pearlite sheets formed. The pearlite sheets formed at A1 ~ 650 ℃ are thicker. When magnified by more than 400 times under the metallographic microscope, parallel wide ferrite and thin cementite can be distinguished, which are called coarse pearlite and lamellar pearlite, referred to as pearlite. When the pearlite formed at 650 ~ 600 ℃ is magnified by 500 times under the metallographic microscope, only a black line can be seen on the cementite of pearlite, The lamellae that can only be distinguished by 1000 times magnification is called sorbite. The pearlite formed at 600 ~ 550 ℃ is magnified by 500 times with a metallographic microscope, and the pearlite lamellae can not be distinguished. Only the black pellet-like structure can be seen. The lamellae that can only be distinguished by 10000 times magnification with an electron microscope is called troostite.

Upper bainite: a mixture of supersaturated acicular ferrite and cementite, with cementite between ferrite needles.

Features: undercooled austenite is a phase transformation product at medium temperature (about 350 ~ 550 ℃), and its typical form is a bundle of ferrite laths with approximately parallel orientation difference of 6 ~ 8od, and carbide short rods or small pieces arranged along the long axis of the lath are distributed among the laths; The upper bainite is typically feather-like, and the grain boundary is the axis of symmetry. Due to different orientations, the feathers can be symmetrical or asymmetric, and the ferrite feathers can be needle-like, dot-like, and block-like. If it is high carbon and high alloy steel, the needle-like feathers cannot be seen clearly; Medium carbon and medium alloy steel with clear needle-like feathers; Low carbon and low alloy steel, with clear feathers and thick needles. During the transformation, the upper bainite is formed at the grain boundary and grows into the crystal without transgranular.

Lower bainite: the same as above, but the cementite is in the ferrite needle.

Features: transformation product of undercooled austenite at 350 ℃ ~ Ms. Its typical form is biconvex lenticular ferrite containing supersaturated carbon, and there are unidirectional carbide flakes distributed in it; It is needle-shaped in the crystal, and the needle leaves do not cross but can be handed over. Different from tempered martensite, martensite is divided into layers, while lower bainite has the same color. The carbonized material point of lower bainite is thicker than that of tempered martensite, which is easy to be eroded and blackened. Tempered martensite has a lighter color and is not easy to be eroded. The carbide dispersion of high carbon high alloy steel is higher than that of low carbon low alloy steel, and the needle leaf is finer than that of low carbon low alloy steel.

Granular bainite: multiphase structure with many small islands distributed in large or strip ferrite.

Features: undercooled austenite is the uppermost transformation product in the bainite transformation temperature zone. At the beginning of formation, it is composed of massive ferrite and small island carbon-rich austenite formed by the combination of strip ferrite. The carbon-rich austenite may remain as retained austenite in the subsequent cooling process; It may also be partially or completely decomposed into a mixture of ferrite and cementite (pearlite or bainite); It is most likely that part of it will be transformed into martensite and part of it will remain to form a two-phase mixture, which is called M-A structure.

Carbide-free bainite: the structure composed of single-phase lath ferrite, also known as ferrite bainite. Features: the formation temperature is at the uppermost part of the bainite transformation temperature zone. The lath ferrite is carbon-rich austenite, and the carbon-rich austenite has a similar transformation in the subsequent cooling process. Carbide-free bainite generally appears in low carbon steel, and it is also easy to form in steel with high silicon and aluminum content.

Martensite: supersaturated solid solution of carbon in a-Fe.

Features: lath martensite: is formed in low, medium carbon steel, and stainless steel. It consists of many parallel laths to form a lath bundle. One austenite grain can be transformed into several lath bundles (usually 3 to 5) lamellar martensite (acicular martensite): it is commonly found in high, medium carbon steel and high Ni Fe Ni Alloys. There is a suture in the needle to divide the martensite into two halves. Due to different orientations, it can be needle-like or massive, The needle and needle are arranged at an angle of 120o, the needle leaf grain boundary of high-carbon martensite is clear, and the fine needle-like martensite is in the form of cloth, which is called cryptocrystalline martensite.

Ledeburite: a eutectic mixture of austenite and cementite.

Features: dendritic austenite is distributed on the cementite matrix.

Tempered martensite: the martensite decomposes to obtain very fine transition carbides and supersaturated (low carbon content) A-phase mixed structure. Features: it is formed by tempering martensite at 150 ~ 250 ℃. This structure is extremely susceptible to corrosion. Under the optical microscope, it is a dark black needle-like structure (maintaining the orientation of quenched martensite), which is very similar to the lower bainite. Only under the high-power electron microscope can very small carbonized material spots be seen.

Tempered troostite: a mixture of carbide and A-phase.

Features: it is formed by tempering martensite at 350 ~ 500 ℃. The microstructure is characterized by the distribution of extremely fine granular carbides in the ferrite matrix. The needle-like morphology has gradually disappeared, but it is still dimly visible. The carbides can not be distinguished under the optical microscope. Only the dark structure can be observed, and the two phases can be clearly distinguished under the electron microscope. It can be seen that the carbide particles have grown obviously.

Tempered sorbite: ferrite is used as the matrix, and uniform carbide particles are distributed on the matrix.

Features: it is formed by high-temperature tempering of martensite at 500 ~ 650 ℃. The microstructure is characterized by a multiphase structure composed of equiaxial ferrite and fine-grained carbide. The traces of martensite flakes have disappeared, and the appearance of cementite has been clear, but it is difficult to distinguish under the light microscope. The cementite particles can be seen under the electron microscope.

Granular pearlite: composed of ferrite and granular carbide.

Features: it is formed by spheroidizing annealing of hypereutectoid steel or tempering of martensite in the temperature range of 650 ℃ ~ A1. It is characterized in that carbides are distributed on ferrite in granular form.

Widmanstatten structure: if the austenite grain is relatively coarse and the cooling rate is relatively appropriate, the pre-eutectoid phase may exist in the form of needle (flake) mixed with flake pearlite, which is called the widmanstatten structure.

Features: the ferrite of Widmanstatten structure in hypoeutectoid steel has a sheet shape, feather shape, or triangle shape, and the coarse ferrite is distributed in parallel or triangle. It appears at the austenite grain boundary, and at the same time, the cementite with widmanstatten structure in the eutectoid steel grows into the grain. The cementite has a needle or rod shape, and it appears in the austenite grain.

Similar Articles:

- Normalizing

- Heat treatment

- Quenching & Tempering

- Normalizing & Annealing

- Quenching and tempering(QT)

- Quenched and tempered steel

- Heat treatment quality inspection

- Heat treatment workshop work instructions

- Explanation of metallographic structure terms

- Factors Affecting Heat Treatment Deformation

- Common heat treatment process of steel castings

- The reasons and effects of steel parts needing quenching and tempering

Recent Articles:

- Casting technical requirements and analysis of common problems of steel castings

- What is the role of Mo in high manganese steel casting production?

- What effect does carbon have on cast steel and iron during smelting?

- Prevention and Analysis of Stainless Steel Casting Defects

- Causes of cracks in steel castings